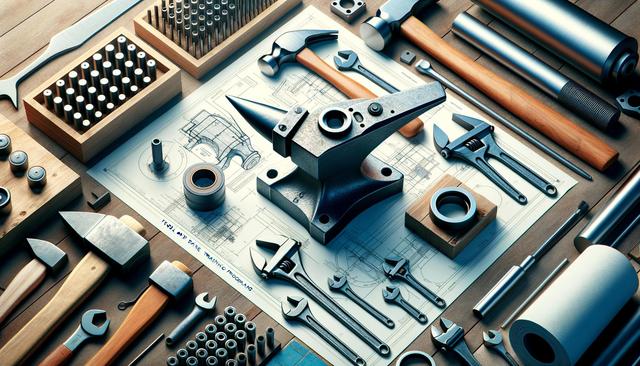

Understanding Tool and Die Training Programs

Tool and die training programs are designed to equip students with specialized skills in designing, building, and maintaining tools, dies, jigs, and fixtures used in manufacturing. These programs are essential for industries that demand precision and efficiency, such as automotive, aerospace, and metal fabrication. The training combines theoretical knowledge with hands-on experience, providing learners with the competencies required to excel in the field. By enrolling in a certified tool and die program, individuals gain access to a structured curriculum that builds a strong foundation in machining, blueprint reading, and computer-aided design (CAD).

Many training programs include modules on safety protocols, material science, and CNC (Computer Numerical Control) operations. These technical aspects are crucial for modern manufacturing environments, where automation and precision play a significant role. Students learn to work with various types of machinery and materials, preparing them for real-world challenges. Tool and die certification is often a key part of these programs, offering official recognition of the skills acquired and enhancing employment prospects.

What You Can Expect to Learn

Tool and die training programs cover a wide range of topics, ensuring that participants are well-prepared to meet industry standards. These programs typically offer comprehensive instruction in areas such as:

- Blueprint interpretation and technical drawing

- Manual and CNC machining techniques

- Tool design and fabrication

- Die making and maintenance

- Mathematics and measurement systems

Participants also receive practical training in using lathes, grinders, milling machines, and other essential tools. These skills are reinforced through lab exercises, apprenticeships, or internships, depending on the program structure. The goal is to develop both the manual dexterity and analytical thinking required in tool and die making.

Furthermore, many training institutions integrate soft skills development, such as teamwork, problem-solving, and communication. These are highly valued in collaborative manufacturing environments and can contribute to career advancement. Graduates of tool and die training programs are often qualified for roles such as toolmaker, die maker, machinist, or CNC technician, with opportunities for further specialization.

The Importance of Certification

Getting certified in tool and die is a significant step toward building a sustainable and rewarding career. Certification validates your skills and demonstrates a commitment to professional development. Employers often prefer candidates who hold recognized certifications, as it assures them of the individual’s competence and training quality. Certification may also be required for certain job positions or to access higher pay grades.

In most regions, tool and die certification involves completing a formal training program followed by passing a practical and theoretical examination. Some certifications are offered by industry associations or technical education boards and are recognized nationally or regionally. Benefits of obtaining certification include:

- Increased job opportunities in various manufacturing sectors

- Higher earning potential with recognized credentials

- Access to advanced roles and responsibilities

- Greater job security and career mobility

Whether you’re entering the workforce for the first time or looking to enhance your current skills, certification is a valuable investment in your professional future.

Choosing the Right Program

When selecting a tool and die training program, it’s important to consider several factors to ensure it aligns with your career goals. Not all programs are created equal, and the right one can make a significant difference in your learning experience. Look for accredited institutions that offer certified training with up-to-date facilities and equipment. A strong curriculum should include both classroom instruction and practical workshops.

Key factors to evaluate include:

- Accreditation and reputation of the training provider

- Availability of hands-on training and modern equipment

- Instructor qualifications and industry experience

- Job placement support and apprenticeship opportunities

- Flexibility in course scheduling (full-time, part-time, or online options)

Some programs also offer partnerships with local manufacturers, which can lead to job placements after graduation. These collaborations provide real-world exposure and help bridge the gap between training and employment. Be sure to research and compare programs thoroughly before making a decision.

Career Outlook and Opportunities

Completing a tool and die training program opens the door to a variety of career paths in the manufacturing sector. As industries continue to evolve with technological advancements, skilled tool and die professionals remain in high demand. From small workshops to large industrial plants, employers seek individuals who can create and maintain the tools necessary for efficient production processes.

Career opportunities for certified individuals include roles such as:

- Toolmaker or Die Maker

- Precision Machinist

- CNC Programmer or Operator

- Manufacturing Technician

- Machine Maintenance Specialist

With experience, many professionals move into supervisory or technical management positions. Others may choose to specialize further in mold making, stamping dies, or progressive tooling. The diverse range of applications makes this field suitable for individuals looking for long-term career growth and stability. Additionally, those with entrepreneurial interests may even consider starting their own tool and die shop after gaining sufficient experience and industry knowledge.

Conclusion: Take the First Step Toward a Fulfilling Career

Tool and die training programs offer a structured path to a stable and rewarding career in manufacturing. By gaining hands-on experience and earning recognized certification, individuals position themselves for long-term success in a field known for precision and innovation. Whether you’re just starting out or seeking to enhance your current skill set, investing in a tool and die program can be a valuable move toward a better future. Explore your options, choose a program that fits your needs, and take the first step toward building a career with lasting impact.

Leave a Reply