Understanding Diesel Equipment and Its Complexities

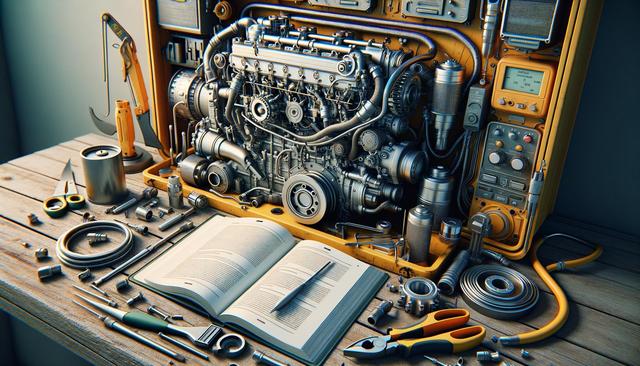

Heavy diesel equipment forms the backbone of many industries, from construction to mining and logistics. Machines like bulldozers, excavators, and cranes require not only skilled operators but also trained technicians who can maintain and troubleshoot their intricate systems. Diesel-powered machinery is known for its durability and power, but it also demands a high level of technical understanding to keep it running efficiently. Maintenance training for diesel equipment delves deep into engine systems, hydraulics, electrical components, and safety protocols. It equips technicians with the knowledge needed to identify issues early and perform preventative maintenance, reducing costly downtime and extending the lifespan of valuable assets.

Diesel equipment maintenance is more than just changing oil or replacing filters. It includes understanding diagnostic tools, interpreting fault codes, and performing complex repairs. Proper training ensures that technicians can work confidently with advanced systems such as Tier 4 Final engines and electronically controlled transmissions. These components are designed for efficiency and emissions compliance, but they also add layers of complexity that only trained professionals can navigate effectively.

Training Programs: What to Expect

Specialized training programs in diesel equipment maintenance are designed to be both comprehensive and practical. These programs typically combine classroom instruction with hands-on experience, allowing students to apply theoretical knowledge in real-world scenarios. A well-rounded curriculum will cover areas such as:

- Diesel engine theory and performance

- Hydraulic system maintenance and troubleshooting

- Electrical systems and diagnostics

- Preventive maintenance procedures

- Safety standards and compliance regulations

Students also learn how to read schematics, use specialized diagnostic tools, and follow manufacturer-specific service procedures. Training can be tailored to different types of heavy equipment, ensuring relevance to various job roles in industries like construction, agriculture, and transportation. Many programs also offer certifications that enhance employability and demonstrate a technician’s competence to prospective employers.

Hands-On Learning for Real-World Application

One of the most valuable aspects of diesel equipment maintenance training is the hands-on experience. Working directly with bulldozers, excavators, and cranes allows students to gain confidence and proficiency. Whether it’s performing a valve adjustment on a diesel engine or troubleshooting a hydraulic leak, practical tasks help solidify learning and prepare students for the demands of the field.

Training facilities often simulate real job site conditions, providing exposure to:

- Heavy lifting and rigging techniques

- Equipment disassembly and reassembly

- Routine and emergency repairs

- Use of diagnostic software and scan tools

This approach not only builds technical skills but also fosters problem-solving abilities and attention to detail—two traits essential for any successful heavy equipment technician.

Career Pathways and Industry Demand

With the growing reliance on diesel-powered equipment in various sectors, the demand for skilled maintenance technicians continues to rise. Graduates of diesel equipment training programs can pursue roles such as field service technicians, maintenance supervisors, and equipment inspectors. These roles often come with opportunities for advancement and specialization, particularly for those who stay current with evolving technologies and certifications.

Employers across industries value technicians who can maintain high-value assets efficiently. Industries that frequently seek trained diesel equipment technicians include:

- Construction and infrastructure development

- Mining and resource extraction

- Agriculture and forestry

- Freight and material handling

By completing a well-structured training program, individuals can enter the workforce with the skills and confidence needed to contribute effectively from day one.

Staying Updated with Evolving Technology

Diesel equipment technology is constantly evolving to meet environmental regulations and improve operational efficiency. As a result, maintenance techniques and diagnostic tools must evolve as well. Continuous learning is a vital part of a diesel technician’s career. Many training institutions offer advanced courses or refresher modules that focus on new technologies, such as hybrid systems or digitally integrated controls.

Staying informed about the latest trends and updates ensures technicians remain valuable assets in their workplaces. Topics often covered in ongoing education include:

- Electronic control modules (ECMs)

- Emission control systems

- Alternative fuel systems

- Telematics and remote diagnostics

Technicians who embrace ongoing education are better positioned to handle the complex needs of modern equipment and to adapt to future advancements in the field.

Conclusion: Building a Skilled, Reliable Workforce

Diesel equipment maintenance training plays a crucial role in preparing individuals for rewarding careers in industries that rely on heavy machinery. By mastering the operation and upkeep of bulldozers, excavators, and cranes, trainees contribute to safer work environments and more efficient project outcomes. The combination of theoretical knowledge, hands-on experience, and continuous learning creates professionals who are ready to meet the demands of a dynamic and evolving industry. For those interested in a stable, technical career path with opportunities for growth, diesel equipment maintenance training is a solid foundation for long-term success.

Leave a Reply