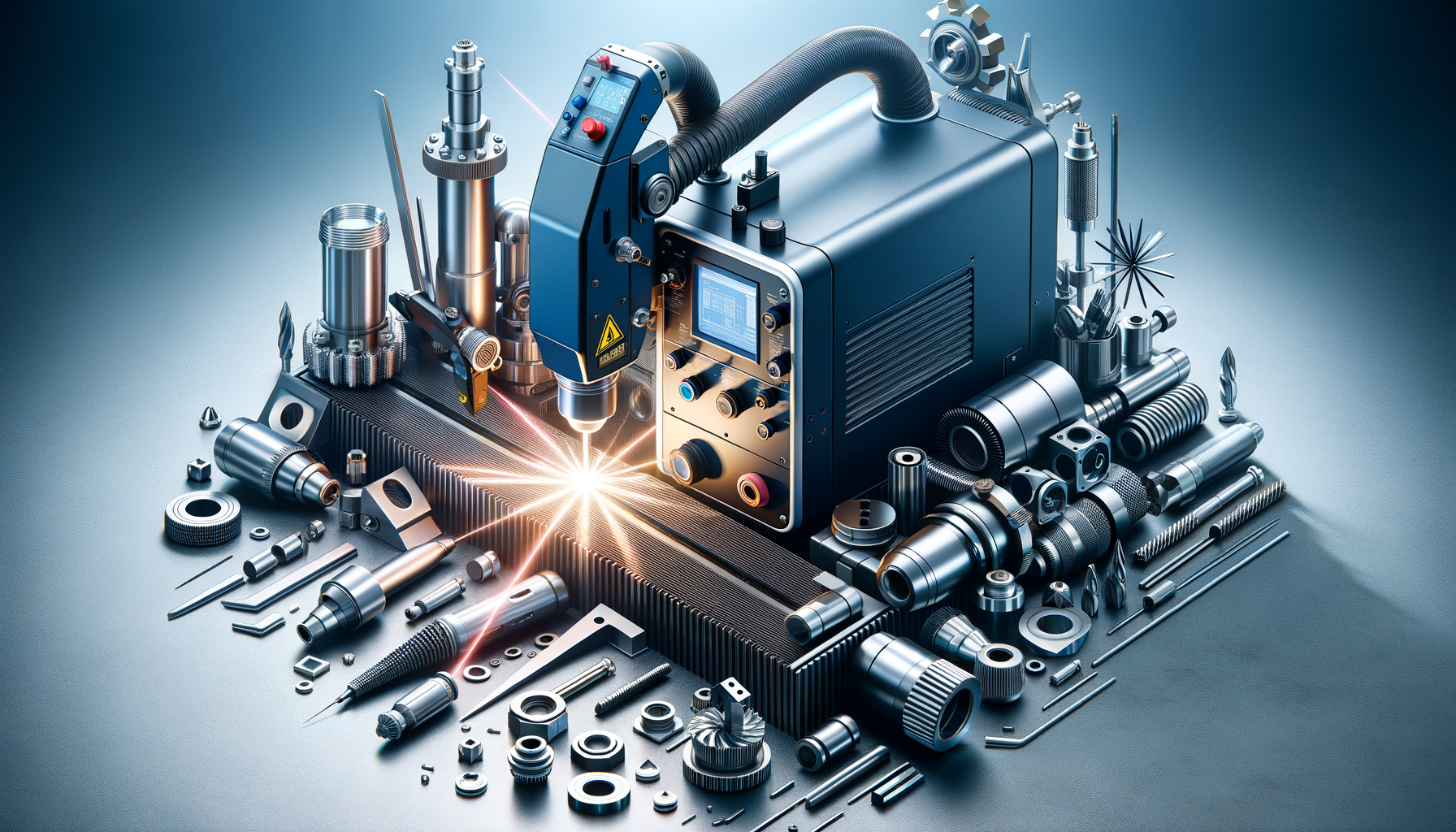

Understanding Laser Welding Technology

Laser welding is a cutting-edge technology that uses a concentrated laser beam to join materials, typically metals. This process is renowned for its precision, speed, and the ability to produce high-quality welds with minimal distortion. Unlike traditional welding methods, laser welding can be used in various industrial applications, ranging from automotive to aerospace, due to its flexibility and efficiency.

The laser welding process involves the emission of a high-intensity laser beam, which melts the materials at the joint, creating a strong bond upon cooling. This method is particularly beneficial for applications requiring detailed and intricate welds. Some of the key advantages of laser welding include:

- High precision and control over the welding process

- Minimal thermal distortion, preserving the integrity of the materials

- Capability to weld dissimilar materials

- Increased speed and productivity compared to traditional methods

These features make laser welding a preferred choice in industries where precision and efficiency are paramount.

Types of Laser Welding Machines

Laser welding machines come in various types, each suited for specific applications and materials. Understanding the differences can help in selecting the right machine for your needs. Here are some common types:

- Fiber Laser Welders: Known for their efficiency and high beam quality, fiber lasers are ideal for welding metals with high reflectivity and thermal conductivity.

- CO2 Laser Welders: These are versatile and can handle a wide range of materials, including non-metals. They are often used in industries that require large-scale welding.

- Diode Laser Welders: These are compact and energy-efficient, making them suitable for precision welding in electronics and medical device manufacturing.

Each type of laser welding machine has its unique advantages, and the choice largely depends on the specific requirements of the task at hand, such as the type of material, thickness, and desired speed of operation.

Applications of Laser Welding Machines

Laser welding machines are employed across various industries due to their versatility and efficiency. Some notable applications include:

- Automotive Industry: Used for welding car bodies, gear parts, and other components, ensuring strong and durable joints.

- Aerospace: Essential for creating lightweight yet strong structures, laser welding is used extensively in the manufacture of aircraft components.

- Medical Devices: The precision of laser welding is crucial in the production of medical instruments and implants, where even minor defects can have significant consequences.

- Electronics: Laser welding is used to connect delicate electronic components without damaging the surrounding materials.

The adaptability of laser welding machines to different materials and thicknesses makes them invaluable in these high-tech industries.

Factors to Consider When Buying a Laser Welding Machine

Investing in a laser welding machine requires careful consideration of several factors to ensure it meets your specific needs. Here are some key considerations:

- Material Compatibility: Ensure that the machine can handle the types of materials you intend to weld.

- Power and Speed: Consider the machine’s power output and speed, which will affect the efficiency and quality of the welds.

- Cost and Maintenance: Evaluate the initial cost and the long-term maintenance requirements of the machine.

- Ease of Use: Look for machines with user-friendly interfaces and controls to minimize training time and increase productivity.

By assessing these factors, you can choose a laser welding machine that aligns with your operational goals and budget constraints.

Conclusion: Making the Right Choice

Laser welding machines represent a significant advancement in manufacturing technology, offering unparalleled precision, speed, and versatility. Whether you are in the automotive, aerospace, medical, or electronics industry, investing in a laser welding machine can enhance your production capabilities and ensure high-quality results.

When selecting a laser welding machine, consider the specific requirements of your applications, the types of materials you work with, and your budget. By making an informed decision, you can unlock the full potential of laser welding technology, driving innovation and efficiency in your operations.

Leave a Reply